Glove Box + Tubular Furnace

This system is a highly integrated and fully functional advanced materials preparation and electrochemical research platform. Its core design concept is to provide a seamless, ultra-low water and oxygen environment for the synthesis, pretreatment, transfer, encapsulation, and high-temperature electrochemical testing of advanced materials (especially alkali metal/alkaline earth metal systems and novel electrode/electrolyte materials) that are extremely sensitive to air and moisture (especially alkali metal/alkaline earth metal systems and novel electrode/electrolyte materials).

Features:

1. Inert Atmosphere Glove Box Workstation

● Function: Serves as the operational center and environmental barrier of the entire system. It is filled with high-purity inert gases (such as Ar and N₂) and equipped with a purification and circulation system to maintain a continuously ultra-low water and oxygen content within the chamber.

● Role: In this environment, all manual operations such as weighing, mixing, and filling air-sensitive raw materials, as well as the removal, crushing, characterization, sample preparation, and vacuum encapsulation of reaction products can be safely performed. It also serves as a "clean corridor" connecting the tube furnace and the electrolytic furnace, enabling safe material transfer.

2. High-Temperature Tubular Furnace (Integrated within the glove box or connected via a transition chamber)

● Function: Provides a precisely controllable high-temperature heat treatment environment.

● Application: Primarily used for pre-sintering, annealing, reduction, carbonization, and other pretreatment processes of materials, or certain solid-phase synthesis reactions requiring stringent atmosphere conditions. After the material is loaded into quartz/corundum tubes in the glove box, it can be directly subjected to high-temperature treatment in the same atmosphere. After cooling, it can be transferred to the next step without exposure, ensuring the purity of the material in its specific phase structure or valence state.

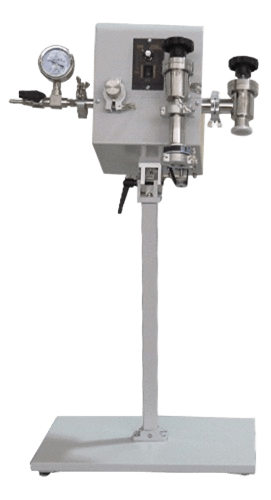

3. Automatic Lifting Well-Type Molten Salt Electrolysis Furnace (Located within the main compartment of the glove box)

● Function: The core device for conducting high-temperature molten salt electrochemical experiments under an inert atmosphere.

● Automatic Lifting Mechanism: Enables programmed lifting and lowering of electrodes (especially working electrodes) within high-temperature molten salt, suitable for electrodeposition of metals/alloys, electrochemical reduction of oxides/minerals (FFC method, OS method), high-temperature electrochemical performance testing of solid/liquid electrode materials, and molten salt electrolytic refining.

● Well-Type Design: The furnace body is deeply embedded within a glove box, with the crucible at the bottom and the electrode system inserted from above, facilitating operation and observation.

● Precise Temperature Control: Similar to high-temperature furnaces, it features precise programmed temperature rise and fall control.

● Integration: Typically equipped with a high-temperature electrode sealed feed system and a multi-channel electrochemical workstation, allowing for real-time monitoring of current, voltage, impedance, and other signals during experiments.

|

Equipment Name |

High Temperature Preheating Oxygen-Free Molten Salt Electrolysis System |

|

|

Specifications |

NBD-HTGB-4G1200-10TIRY/1780N |

|

|

Molten Salt Electrolysis Furnace |

Power Supply |

220 V 50 / 60 HZ |

|

Rated Power |

3.5 KW |

|

|

Temperature Control Accuracy |

±1 ℃ |

|

|

Heating Element |

Alloy Resistance Wire |

|

|

Sensor Type |

Type K Thermocouple |

|

|

Maximum Temperature |

1200 ℃ |

|

|

Rated Temperature |

1150 ℃ |

|

|

Recommended Heating Rate |

≤10 ℃ / min |

|

|

Furnace Temperature Zone Dimensions |

φ150 × 200 mm (Single Temperature Single Control) |

|

|

Reaction Vessel Specifications |

310S Material, Effective Space: Inner Diameter φ104 × 360 mm |

|

|

Crucible Specifications |

Corundum Material φ60 × 60 mm |

|

|

Flow Meter Type |

1-channel Float Flow Meter 20 – 200 ml / min |

|

|

Air Inlet |

φ6.35 mm Double Compression Fitting |

|

|

Exhaust Port |

12mm Pagoda Head |

|

|

Vacuum Pump |

DRV5 KF25 Interface |

|

|

Water Chiller Capacity |

5 L |

|

|

DC Power Supply Specifications |

800 W(10 V 80 A) |

|

|

High Temperature Tube Furnace |

Power Supply |

220 V 50 / 60 HZ |

|

Rated Power |

4.5 KW |

|

|

Temperature Control Accuracy |

±1 ℃ |

|

|

Heating Element |

High Purity Molybdenum Silicon Rod |

|

|

Sensor Type |

Type B Thermocouple |

|

|

Maximum Temperature |

1700 ℃ |

|

|

Rated Temperature |

1650 ℃ |

|

|

Recommended Heating Rate |

≤10 ℃ / min |

|

|

Furnace Chamber Temperature Zone Dimensions |

Length 300 × Height 112 × Depth 160 mm |

|

|

Furnace Tube Specifications |

Corundum Tube φ80 × 1000 mm |

|

|

Air Inlet |

φ6.35 mm Double Compression Fitting |

|

|

Exhaust Outlet |

8.4 mm Pagoda Head |

|

|

Overall Equipment Dimensions |

Length 4420 × Height 2015 × Depth 1050 mm |

|

◎ CE Certified

◎ Brand / NOBODY