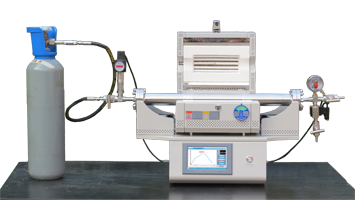

Tubular furnace (high temperature and high pressure type)

Features:

1. Three-layer safety protection ensures peace of mind during work;2. High-pressure ring heater ensures uniform temperature distribution;

3. Modular structure ensures durability and easy maintenance;

4. Voltage stabilization ensures safety and reliability;

5. Simple and convenient one-touch operation with 15 pre-stored working curves for flexible operation;

6. Real-time sintering temperature and power monitoring ensures safety and energy conservation.

|

Product Model |

NBD-HP1200-2350TIY-D |

||||||||||||

|

Electrical Specifications |

AC220V 1.5KW |

||||||||||||

|

Permitted Temperature and Pressure |

The temperature depends on the gas pressure. Please refer to the table below for details:

High-temperature and high-pressure tubing is a consumable component. Please replace it immediately if you notice any deformation. |

||||||||||||

|

Chamber Specifications |

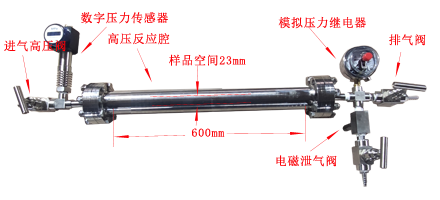

1. Dimensions: Sample constant temperature zone Φ23mm × 120mm (Additional specifications available upon request)

|

||||||||||||

|

Furnace Structure |

1. Openable double-layer structure, convenient for customers requiring rapid temperature reduction. The shell surface temperature is less than 60°C.

|

||||||||||||

|

Gas and crucible access available. |

1. Oxidizing and protective atmospheres, as well as inert gases such as N2, Ar, and He, are supported.

|

||||||||||||

|

Control System |

1. 15 pre-stored temperature curves, each with 30 temperature-time axis segments, eliminating the hassle of repeated setup for different experimental processes.

|

||||||||||||

|

Temperature Accuracy |

+/- 1℃ |

||||||||||||

|

Device Dimensions and Weight |

800 x 450 x 350mm 45KG |

||||||||||||

|

Heating Element |

Molybdenum-doped Iron-Chromium Aluminum Alloy |