Vacuum heating furnace (tungsten filament heater) 2200℃

Features:

1. Furnace Body:Utilizes a double-layer water-cooled structure, with upper and lower flanges welded together to form a cylindrical structure. The inner wall is finely polished 304 stainless steel to ensure high vacuum levels, while the outer wall is sandblasted and water-cooled. A monitoring thermocouple and observation window are located on the side of the furnace body. The monitoring thermocouple monitors the temperature of the metal heat shield on the side to prevent excessive temperatures outside the shield.

2. Furnace Cover:Also utilizing a double-layer water-cooled structure, both the upper and lower large furnace covers and the center small furnace cover are double-layer water-cooled flat covers. The inner wall is finely polished 304 stainless steel to ensure high vacuum levels.

3. Furnace Bottom and Lifting Mechanism:The furnace bottom utilizes the same structure as the furnace cover, with a loading platform located on the center small furnace bottom. Loading and unloading are performed from below, and the lifting system utilizes a linear guide system.

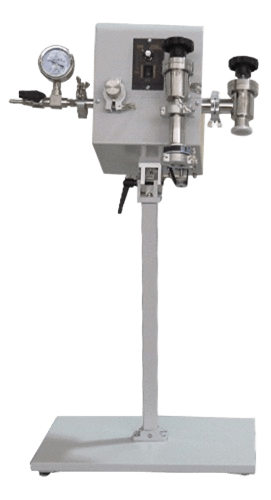

4. Vacuum Acquisition and Measurement System:The vacuum acquisition system consists of a molecular pump, a mechanical pump, vacuum piping, a bleed valve, a pneumatic butterfly valve, and a vacuum pressure gauge.

5. Temperature Field:The heating element utilizes a high-purity tungsten wire mesh heater. Two tungsten meshes are suspended vertically within the furnace. Two tungsten electrodes extend from the sides, perpendicular to the tungsten meshes. Water-cooled copper electrodes are connected to the sides of the furnace, leading outside the furnace and connecting to a transformer.

6. Heating Zone Temperature Control:WRe5/26 tungsten-rhenium thermocouples are used throughout.Using Environment: Tungsten-rhenium thermocouples are highly oxidizable and are suitable for use in inert or dry hydrogen atmospheres, or with a dense protective tube to isolate them from oxygen.

7. Sample Holder System:The sample holder consists of one φ80*6mm tungsten plate, five high-purity tungsten sheets, eight molybdenum sheets, one stainless steel plate, and a high-purity tungsten rod.

8. Water Cooling System:Cooling water enters through a main pipe and is delivered through various branch pipes to the furnace body, furnace cover, electrodes, diffusion pump, and other areas requiring cooling before being discharged.

9. Electrical Control System:The furnace body and vacuum system are both installed on one side of the electrical control cabinet, forming an integrated structure. The transformer is housed within the control cabinet, and the electrical control system is centralized within the cabinet. It utilizes silicon controlled temperature control, and the panel features a touchscreen, ammeter, voltmeter, and vacuum gauge. The control cabinet follows a standard electrical control cabinet structure and integrates a ventilation system. The electrical control system also features alarms for overcurrent, water outage, overtemperature, and burnout.

10. Automatic Exhaust Gas Ignition System:A double-helix silicon carbide rod serves as the ignition source. Once the combustible gas is activated, the coils begin heating, preparing for ignition. The ignition system also includes a built-in flashback protection device, ensuring peace of mind for customers.

|

型號 |

NBD-B2200-80TIGF |

|

Electrical Specifications |

AC3 × 380V 50/60Hz |

|

Rated Power |

20 KW |

|

Tmax |

2200 ℃ (Nominal 2000°C) |

|

Working Area Dimensions |

φ80 × 80 mm |

|

Number of Temperature Control Zones |

1 Zone |

|

Ultimate Vacuum in Cold State |

6.67 × 10-3Pa |

|

Pressure Rise Rate |

≤ 4 Pa/h |

|

Filling Pressure |

≤ 0.015 MPa |

|

Filling Medium |

Argon, Nitrogen, Dry Hydrogen |

|

Temperature Control Thermocouple |

Tungsten-Rhenium Thermocouple φ0.5 × 400 mm |

|

Heater Material |

Tungsten Cage Heater φ117 × 210 mm |

|

Inlet System |

Two-way Variable Area Flowmeter with Solenoid Valve Control |

|

External Dimensions |

Length 1200 × Height 2050 × 950mm Depth |

◎ CE Certified

◎ Brand: NOBODY