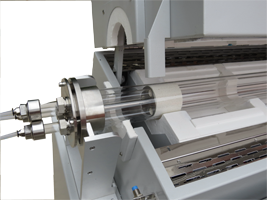

Tubular furnace (multi-temperature zone type)

Features:

1. Furnace tubes made of high-purity quartz or stainless steel offer superior corrosion resistance and high-temperature resistance.

2. High-purity Al2O3 fiber refractory insulation provides excellent insulation and reduces power consumption.

3. The furnace body features a double-layer air-cooled structure with an automatic lift system for opening the top cover.

4. Sintering process curve setting: Dynamically displays the set curve. The equipment can pre-store multiple process curves, each of which can be freely configured.

5. Scheduled sintering allows for unattended sintering using process curves.

6. Real-time display of sintering power, voltage, and other information, along with data recording and export for paperless record keeping.

7. Remote control allows for real-time monitoring of equipment status.

8. Temperature correction: The difference between the main control temperature and the sample temperature is used to perform nonlinear correction throughout the sintering process.

9. The integrated equipment includes a multi-gas supply system, a multi-zone heating system, and a high vacuum system.

|

Product Temperature Zones |

Three Temperature Zones |

Four Temperature Zones |

Five Temperature Zones |

Six Temperature Zones |

|

Furnace Tube Dimensions |

Φ25 / Φ50 / Φ60 / Φ80 / Φ100 × 1600 mm |

|||

|

Operating Temperature |

≤1150℃ |

|||

|

Heating Zone Options

(Customizable)

|

200mm×3/ 200+300+200 mm/ 200+400+200 mm/ 300mm×3/ 300+400+300 mm |

200mm×4/ 200+300+300+200mm/ 200+400+400+200mm/ 300mm×4/ 300+400+400+300mm |

200mm×5/ 300mm×5 |

200mm×6/ 300mm×6 |

|

Heating Rate |

≤20℃/s |

|||

|

Electrical Specifications |

AC380V 6 ~ 10KW |

AC380V 8 ~ 14KW |

AC380V 10 ~ 15KW |

AC380V 12 ~ 18KW |

◎ CE Certified

◎ Brand / NOBODY