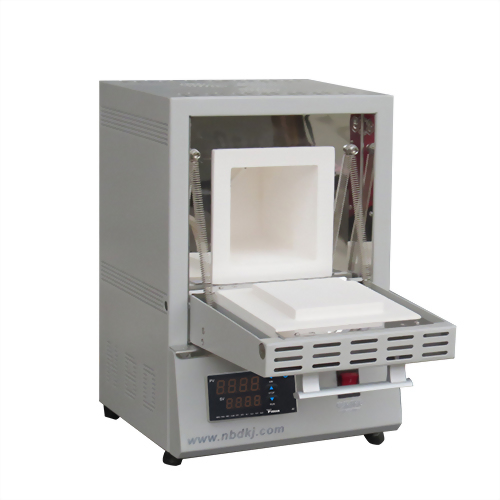

Vacuum atmosphere furnace

A vacuum atmosphere furnace is a device specifically designed for material processing, heat treatment, and chemical reactions in a high vacuum or specialized atmosphere. It is widely used in fields such as metallurgy, semiconductor manufacturing, new materials research and development, and the chemical industry. By precisely controlling atmosphere conditions (such as vacuum, inert gas, reducing gas, etc.) and temperature, this equipment ensures efficient material processing under contamination-free conditions. Vacuum atmosphere furnaces can significantly improve material quality and performance and are suitable for experiments and production processes with extremely stringent environmental requirements.

Features:

1. High-purity Environment

● High-efficiency Vacuum Pump: An optional high-efficiency vacuum pump system can quickly evacuate the furnace to a high vacuum (typically up to 10^-6 Torr), ensuring oxygen-free and contamination-free processing.

● Atmosphere Control System: Capable of handling a variety of atmospheres, including vacuum, inert gas (argon, nitrogen), and reducing gas (hydrogen), to meet diverse process requirements.

2. Uniform Heating

● Temperature Control Accuracy: Utilizing an advanced PID temperature control system with support for multi-stage program control, it ensures high temperature control accuracy and excellent repeatability.

● Temperature Uniformity: Optimizing the heating element layout and temperature control system ensures uniform temperature distribution within the furnace, avoiding local overheating or cold spots.

3. Precise Atmosphere Control

● Atmosphere Switching Device: Allows experiments to be conducted under different atmospheres, such as switching from one atmosphere to another.

● Gas Flow Controller: Precisely controls gas flow and ratio, ensuring a stable and consistent atmosphere.

● Pressure Regulation: Select models are equipped with a pressure regulator to ensure that the atmosphere pressure remains within the set range.

4. Safety Design

● Multiple Protections: Built-in over-temperature protection, over-current protection, and emergency stop buttons ensure safe operation.

● Leak Detection: Equipped with pressure and gas leak detection devices, the device monitors leaks in real time to ensure safety.

● Explosion-Proof Design: For applications requiring the use of flammable gases (such as hydrogen), the device features an explosion-proof design to ensure safety under extreme conditions.

5. Convenient Operation

● Touchscreen Control Interface: Equipped with a touchscreen control interface, it supports data logging and remote monitoring, making operation simple.

● User-Friendly: A user-friendly interface makes operation and maintenance easy.

● Preset Programs: A variety of preset heating programs and atmosphere conditions are provided, allowing users to easily select the appropriate process parameters based on their specific needs.

|

Equipment Name |

Vacuum Atmosphere Furnace |

|

Specifications |

VBF-1200 (200 × 200 × 300) |

|

Power Supply |

Three-phase 380V 50 / 60HZ |

|

Rated Power |

45KW |

|

Number of Temperature Zones |

Single Temperature, Single Control |

|

Sensor Type |

S-type Thermocouple Φ8 × 300 mm |

|

Float Flowmeter |

20-200L / min |

|

Tmax |

1300℃ (Operating Temperature: 1200°C at Room Temperature) |

|

Furnace Material |

304 Stainless Steel Plate + Molybdenum Plate |

|

Furnace Dimensions |

Φ392 × 410 mm |

|

Effective Working Dimensions |

L 200 × H 200 × D 300 mm |

|

Recommended Heating Rate |

≤10℃ / min |

|

Vacuum Pump |

BSV90 KF40 Interface (Ultimate vacuum 4 Pa) |

|

Molecular pump |

Air inlet CF200, air outlet KF40 (Ultimate vacuum 5*10^-6Pa) |

|

Ultimate vacuum of the entire unit |

6.7*10^-3Pa (empty furnace, cold state) |

|

Furnace dimensions |

L 1835 mm × H 2040 mm × D 1625 mm |

|

Water chiller dimensions |

L 706 mm × H 1235 mm × D 1035 mm |

◎ CE certified

◎ Brand: NOBODY