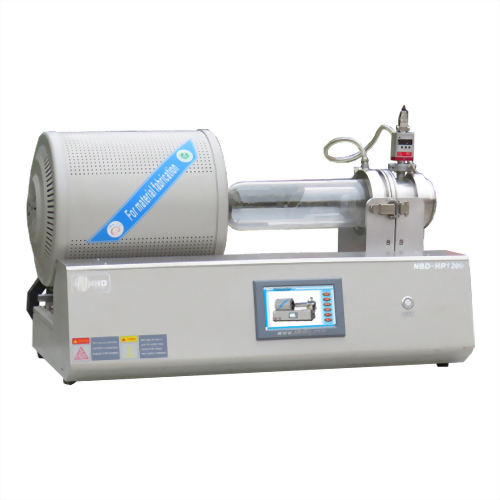

Vacuum tubular annealing furnace

Features:

1. High-Temperature Capability

● Maximum Temperature: The maximum operating temperature reaches 1500°C, with some models capable of higher temperatures.

● Rapid Heating: High-efficiency silicon carbide heating elements ensure rapid temperature rise and shorten heating time.

● Temperature Uniformity: Uniform temperature distribution within the furnace ensures a consistent temperature environment for all sample positions.

2. High Vacuum Environment

● Vacuum Degree: Able to achieve a vacuum degree of 10^-5 Pa or higher, ensuring high-temperature processing in an oxygen-free environment.

● Vacuum Gauge: Real-time monitoring of the vacuum degree within the chamber ensures the required vacuum level is achieved.

3. Atmosphere Control

● Multiple Atmospheres: Supports a variety of atmospheres, including air, vacuum, inert gases (such as nitrogen and argon), and reducing gases.

● Atmosphere Control System: Equipped with an advanced atmosphere control system, it precisely controls gas flow and ratios to ensure a stable and consistent atmosphere.

4. Precision Control

● PID Temperature Control System: Utilizes an advanced PID temperature control system with multi-stage program control, ensuring high temperature control accuracy and excellent repeatability.

● Real-time Monitoring: Equipped with a high-precision temperature sensor, it monitors and records temperature changes within the furnace in real time.

● Overtemperature Protection: Built-in overtemperature protection prevents accidents caused by temperature runaway.

5. Convenient Operation

● Touchscreen Control Interface: Equipped with a touchscreen control interface, it supports data logging and remote monitoring for easy operation.

● Program Storage: Multiple heating programs can be set and saved for easy reuse.

6. Safety Design

● Multiple Protection Measures: Built-in overtemperature protection, overcurrent protection, and other safety measures ensure safe operation.

● Emergency Stop Function: Rapidly cuts power in the event of an emergency, ensuring the safety of personnel and equipment.

● Pressure Relief Valve: Equipped with a pressure relief valve, it automatically releases pressure in the event of overpressure, preventing accidents.

● Leak detection: Equipped with pressure and gas leak detection devices to monitor leaks in real time to ensure safety.

|

Specifications |

NBD-O1500-100TP2DZY-N |

|

Power Supply |

Three-phase 380V 50/60HZ |

|

Rated Power |

15KW |

|

Sensor Type |

Single Platinum-Rhodium S-type Thermocouple |

|

Tmax |

1500 ℃ |

|

Rated Temperature |

1450 ℃ |

|

Number of Temperature Zones |

Single Temperature Dual Control |

|

Heating Rate |

1℃ / H-20℃ / Min |

|

Furnace Space |

L640 * H160 * W140 mm |

|

Furnace Tube Material and Dimensions |

High-purity Corundum φ100 * 1200 mm |

|

Mass Flow Meter |

S500 5000SCCM φ6.35 Dual Ferrule Fitting, Nitrogen Calibrated |

|

Inlet Specifications |

φ6.35 Dual Ferrule Fitting |

|

Outlet Specifications |

φ8 Pagoda Fitting |

|

Furnace Dimensions |

Length 1400 * Height 1430 mm x Depth 900 mm |

◎ CE Certified

◎ Brand: NOBODY