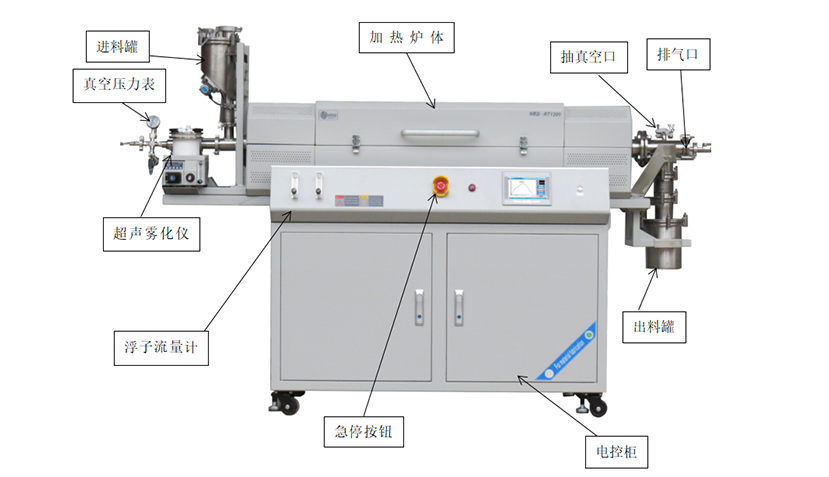

Rotary furnace (automatic feeding and discharging type with atomizer)

Features:

1. An automatic loading and unloading system equipped with radio frequency admittance level switches and a stainless steel auger for efficient material loading and unloading, as well as continuous material level monitoring.

2. A proprietary atomizer provides a stable supply of liquid reactants for experiments.

3. Advanced PID self-learning fuzzy control ensures high temperature control accuracy, maintaining ±1°C.

4. The furnace lining is constructed of lightweight, high-purity alumina fiber material, providing enhanced insulation and reducing energy consumption.

5. Internet of Things (IoT) functionality (Wi-Fi) allows for remote monitoring and operation of the equipment via mobile phone or computer.

6. Data storage allows for the storage of key sintering parameters for up to 30 days (with the machine running for 8 hours per day).

7. Recipe function allows for the pre-storage of over 20 recipes.

8. Networking: The system connects to a host computer via an RJ45 port using TCP/IP (the host computer requires the appropriate software).

|

Specifications |

NBD-RT1200-60T3D2F2LN |

|

Power Supply |

Three-phase 380V 50/60HZ |

|

Rated Power |

9kw |

|

Number of Temperature Zones |

Single Temperature, Three Controls |

|

Temperature Control Accuracy |

±1℃ |

|

Sensor Type |

K-type Thermocouple Φ2-420 mm |

|

Tmax |

1150℃ |

|

Recommended Heating Rate |

10℃ / min |

|

Temperature Zone Length |

φ150 × 905mm |

|

Furnace Tube Material and Dimensions |

310S Stainless Steel Tube φ60 × 1500mm |

|

Lifting Parameters |

Angle 0-21° Travel 300 mm Speed 5 mm / min s |

|

Auger Feed Reduction Ratio |

10:1 |

|

Furnace Tube Rotation Reduction Ratio |

25:1 |

|

Inlet and Outlet Tank Capacity |

3L |

|

Furnace Tube Effective Volume |

3L |

|

Float Flowmeter |

0.1-1L / min |

|

Inlet Port Specifications |

Φ6.35 Double Ferrule Fitting |

|

Exhaust Port Specifications |

Φ8 Pagoda Connector |

|

Pressure Protection |

Overpressure Safety Valve with Automatic Pressure Relief |

|

Furnace Body Dimensions |

2600mm L × 1600mm H × 760mm D |

|

Heating Element |

Resistance Wire |

|

Vacuum Pump |

KF16 4C |

|

Weight |

Weight |

◎ CE Certified

◎ Brand / NOBODY