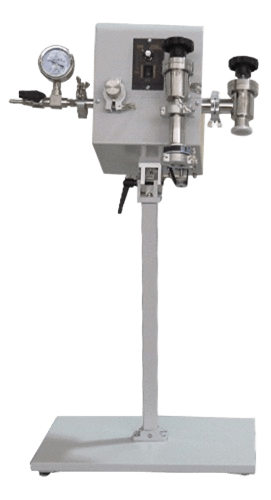

Joule flash furnace (flash evaporator)

A Joule flash sintering furnace, also known as a flash furnace or Joule thermal flash sintering equipment, is an advanced material preparation technology that uses a transient high current to heat a material to its sintering temperature in an extremely short time (milliseconds to seconds). Its core lies in ultra-rapid heating and an internal heat source, enabling ultra-fast densification of materials while effectively inhibiting grain growth, resulting in materials with ultra-fine grains, high density, and excellent properties. Its applications are primarily concentrated in cutting-edge materials science and high-end manufacturing.

Features:

1. Technical Characteristics: Core Advantages Surpassing Traditional Equipment

● Based on the fusion logic of "Joule heating + flash evaporation," this equipment exhibits three core characteristics, perfectly meeting the needs of efficient, energy-saving, and high-performance material preparation.

2. Ultimate Efficiency: Complete the Entire Process in Seconds

● Integrated Synthesis and Sintering:

Under traditional processes, there's no need to first synthesize powder and then sinter it separately. Starting directly from raw material powders (such as metal oxides, carbon source powders, and composite powders), the entire process—from synthesis to impurity removal to densification—can be completed in one step via Joule thermal flash evaporation, shortening the process by over 90%. Example: In preparing barium titanate ceramics, traditional processes require first synthesizing barium titanate powder (2-4 hours) and then sintering it into ceramic (8-12 hours); while the Joule thermal flash evaporation furnace can directly use a mixture of TiO₂ and BaCO₃ powders, completing the reaction and densification within 20-30 seconds, with the total time being only 1/100th of the traditional process.

● No Thermal Hysteresis Waste:

Heat acts directly on the material, eliminating the need to wait for the furnace to heat up and maintain a specific temperature. It can quickly enter the processing state after startup, making it particularly suitable for small-batch, multi-variety material development scenarios.

3. Significant Energy Savings:Energy utilization rate increased by over 50%

● Precise Energy Focusing:

The current acts only on the powder area to be processed. The furnace body itself consumes almost no energy, avoiding the energy loss of traditional furnaces where "heat is stored in the insulation layer and dissipated from the furnace cavity." Thermal efficiency can reach 80%-95% (compared to only 20%-40% for traditional sintering furnaces).

● Low-Temperature Equivalent Effect:

The flash evaporation mechanism allows densification to be achieved at "relatively low temperatures" (20%-40% lower than traditional sintering temperatures). For example, in the preparation of alumina ceramics, traditional sintering requires temperatures above 1600℃, while this equipment can complete the process at 1000-1200℃, further reducing energy consumption.

4. Material Performance Optimization: Fine Grain, High Density, Low Impurities

● Inhibited Grain Growth:

The rapid heating and cooling process effectively prevents excessive growth of powder particles at high temperatures, resulting in a fine-grained structure (grain size typically 1/5-1/10 of that achieved in traditional processes). This improves the material's strength, hardness, toughness, and other mechanical properties by 20%-50%.

● Reduced Impurity Residue:

During flash evaporation, adsorbed water, organic matter, and other impurities on the material surface are instantly vaporized and promptly removed (some equipment is equipped with a rapid vacuum system). This results in a higher purity final product, making it particularly suitable for impurity-sensitive electronic materials (such as ceramic capacitors and semiconductor substrates).

● High Density:

The "transient melting-rapid fusion" at particle contact points reduces porosity, achieving a densification rate typically exceeding 95%, even approaching the theoretical density. This avoids the "internal porosity" problem common in traditional sintering processes.

|

Specifications |

NBD-RTP3000-S |

|

Power Supply |

AC220V 50/60 HZ |

|

Rated Power |

4KW |

|

DC Power Supply |

300V10A Input 220V Power 3KW |

|

DC Single Pulse Power Supply |

30V100A Input 220V Power 3KW |

|

Total Capacitor Capacity |

108mF |

|

Temperature Range |

400-3600℃ |

|

Heating Element |

Graphite |

|

Temperature Sensing Element |

Infrared Thermometer (Range 400-3600℃) |

|

Cavity Dimensions |

Inner Diameter Φ315 × 200 mm |

|

Air Inlet / Outlet |

Air Inlet:φ6.35 Double Fitting

Air Outlet:φ8.4 Pagoda Outlet

|

|

Float Flow Meter |

0.5-8L / min |

|

Furnace Body Filling Pressure |

<0.03 MPa |

|

Vacuum Pump |

DRV16 KF25 Connector |

|

Furnace Dimensions |

Length 1000 × Height 1275 × Depth 800 mm |

◎ CE Certified

◎ Brand / NOBODY