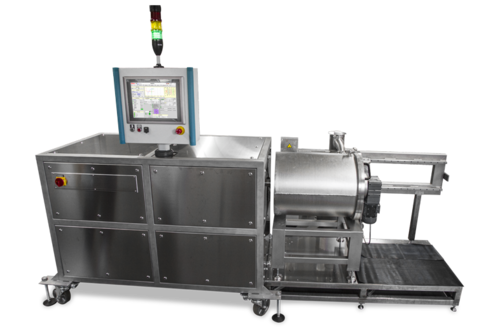

Parylene P260 / PARYLENE COATING SYSTEM

Characteristics and Benefits:

Parexylene coatings offer numerous advantages.

● Complete compatibility, meaning they can even adapt to complex substrate contours, such as sharp edges, drill holes, or blind holes.

● Pinhole-free coating thickness of approximately 0.5 micrometers.

● Chemically insoluble, resistant to a wide range of chemicals.

● Excellent barrier properties against moisture and chemicals.

● High dielectric strength.

● Dry lubrication properties (low coefficient of friction).

● Hydrophobic: H₂O downwell angle is between 92° and 98°.

● Transparency between 90% and 96% in the visible wavelength range (depending on type).

● Biocompatibility: C-type and N-type parexylenes can be individually certified to USP VI, ISO 10993, and FDA standards.

Specifications:

● Dimensions: 1000mm x 2000mm x 2600mm (W x H x D)

● Vacuum Deposition Chamber: Diameter 640 mm, Height 800 mm, Volume approx. 260 liters

● Rotating Mount: Diameter 560 mm, Height 650 mm

● Coating Substance: Parylene N, C, D, F-VT 4

● Possible Coating Thickness: 0.05 to 50 micrometers

● Pyrolysis Tube: 4 kW / Maximum 850 °C

● Cold Trap: Liquid nitrogen or electromechanical cooler

● Vacuum System: Two-stage rotary vane pump

● Pumping Speed: 65 m³/h

● Ultimate Vacuum Pressure: 1 x 10⁻³ mbar

● Power Supply: 230V/16A, 50/60Hz

● Control: PC control (Microsoft Windows 10 IoT)

Brand: Diener Germany, CE